What is Bronze? Bronze is a metal resulting from an alloy. One of the oldest in human history. Learn more about what it is and more …

Bronze is a metallic alloy of copper and tin. Copper constitutes its base and tin appears in a proportion of 3 to 20%. The average bronze alloy is 89% copper and 11% tin. But maybe you will ask what is an alloy?

What is the alloy?

An alloy is a combination or mixture of metallic properties of two or more solid metal elements. The alloys consist of metallic elements such as Fe (iron), Al (aluminum), Cu (copper), Pb (lead). In general, different metallic materials are combined in the alloys, although one can also be combined with a nonmetallic one to alter its properties.

In the cases of alloys to a non-metallic material we can mention P (phosphorus), C (carbon), Si (silicon), S (sulfur), As (arsenic). They are considered mixtures since there are no chemical reactions between the elements together, that is, their atoms do not intertwine or change the constitution of their molecules.

The alloys have a metallic luster and high electrical and thermal conductivity, although usually less than pure metals. The physical and chemical properties are, in general, similar to that of metals. However, the mechanical properties such as hardness, ductility, and toughness can be very different, hence the interest in these materials.

Alloys do not have a unique melting temperature, depending on the concentration, each pure metal melts at a different temperature. There are certain specific concentrations of each alloy for which the melting temperature is unified. This concentration and the alloy obtained are called eutectic. And they have a lower melting point than the melting points of the independent components.

Historically, most alloys were prepared by mixing molten materials.

More recently, powder metallurgy is an alloying process applied in the manufacture of metal objects based on fine powders. After compaction to give them a specific shape, they are heated in a controlled atmosphere to obtain the piece.

This process is suitable for the manufacture of a large series of very small pieces of great precision. Also for unusual materials or mixtures and to control the degree of porosity or permeability. Some typical products are bearings, cutting tools, piston segments, valve guides, filters, etc.

A bit of Bronze History

The oldest known tin-based alloys date back to the fourth millennium BC. C.

The technique consisted of mixing the copper ore – usually chalcopyrite or malachite – with that of tin (cassiterite) in an oven fed with charcoal. The carbon in the charcoal reduced the minerals to copper and tin that melted and alloyed with 5 to 10% by weight of tin. Metallurgical knowledge of the manufacture of bronze gave rise to the so-called Bronze Age in different civilizations.

In some civilizations, such as Egypt, arsenic was used. That allowed to obtain a superior natural alloy, called arsenical bronze. This alloy, with no less than 2% arsenic, was used during the Bronze Age for the manufacture of weapons and tools. This happened considering that the other component, tin, was not frequent in many regions, and should be Imported from faraway places.

The presence of arsenic makes this alloy highly toxic, since it produces, among others, pathological effects.

You may also like…

Bronze in Egypt

In Ancient Egypt, most of the metallic elements that were made consisted of copper alloys with arsenic, tin, gold, and silver.

In tombs of the New Empire, or inside the Karnak temple, bas-reliefs are showing a foundry dating from the 15th century BC. C.

Bronze in Greece

Greece is known for its sculptural tradition in marble. It is known that they also developed advanced bronze casting techniques as proven by the “Riace bronzes”, originated in the 5th century BC. C.

The Bronzes of Riace, also known as Los Guerreros de Riace, are a pair of Greek statues from the 5th century BC. C. that is exhibited in the National Museum of Magna Grecia in Reggio Calabria.

The two bronzes are original Greek works of art from the 5th century BC. C. and its discovery have encouraged scholars to investigate their identity and their authors. However, controversy persists regarding dating, origin, and authorship of the two sculptures.

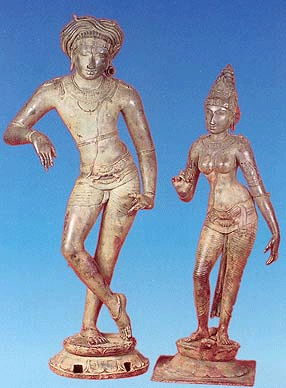

Bronze in India

In India, the artistic plenitude of the Chola Dynasty produced remarkable sculptures between the 10th and 11th centuries of our era, representing the different forms of the god Shivá and other deities.

Bronze in America

The civilizations of pre-Hispanic America knew all the use of bronze alloys. Although many utensils and tools continued to be made of stone. Objects made of binary copper-silver, copper-tin, lead copper and even unusual brass alloys have been found, even in the colonial era, the most important foundries were in Peru and Cuba, mainly dedicated to the manufacture of bells and cannons.

Advantages of bronze

Bronze is harder than copper as a result of alloying copper with tin or other metals and it is easier to melt. It is also harder than pure iron and much more resistant to corrosion.

The bronze used for bells, is characterized by its sound quality when struck, is a bronze with a high tin content of 20 to 25 percent.

Bronze resists corrosion, even that of marine origin, and they are better conductors of heat and electricity.

Another differential feature of bronze alloys concerning steel is the absence of sparks when struck against hard surfaces. This property has been used to manufacture hammers, mallets, adjustable wrenches and other tools for use in explosive atmospheres or the presence of flammable gases.

Another use was in the manufacture of cannons after the manufacture of gunpowder.

Different types of bronzes

Alpha Bronze

The “alpha bronze” is the solid mixture of tin in copper that contains approximately 88% copper and 12% tin. For the manufacture of coins, springs, turbines and cutting tools, a 5% tin alloy is used.

Statuary Bronze

Statuary bronze, with a tin content of less than 10 percent and a mixture of zinc and lead, is technically a brass.

Phosphor Bronze

Phosphor bronze, This bronze is improved in hardness and strength by adding a small amount of phosphorus. This bronze may contain 1 or 2 percent phosphorus in the ingot and a mere trace after molding, but its strength is improved for applications such as pump pistons, valves, and bushings.

Manganese bronzes

Manganese bronzes also useful in mechanical engineering are manganese bronzes, in which there may be little or no tin, but considerable amounts of zinc and up to 4.5 percent manganese.

Aluminum Bronzes

Aluminum bronzes contain up to 16% aluminum and small amounts of other metals such as iron or nickel. They are especially strong and resistant to corrosion. They are cast or forged in pipe fittings, pumps, gears, ship propellers, and turbine blades.

Sun Bronze

Sun bronze is an alloy used in jewelry, tough, ductile and very hard, which melts at temperatures close to those of copper (1357 ° C) and is made up of 60% cobalt.

Arsenical Bronze

Arsenical bronze is the first bronze used by man, it is a whitish alloy, very hard and fragile. It is manufactured in a proportion of 70% copper and 30% arsenic, although it is possible to melt bronze with arsenic percentages of up to 47.5%. In these cases, the result is a bright gray material, fused to red and not altered by boiling water.

The simple exposure to air of arsenical bronze produces a dark patina.

The aluminum Cupro

The aluminum cupro is a type of bronze, similar in color to gold, in which aluminum is the main alloy metal that is added to copper. A variety of aluminum bronzes, of different compositions have found industrial use.

Ordinary Bronze

Ordinary bronze is composed of 90 to 91% copper and 9 to 10% tin, used in the manufacture of cannons and weapons such as bombs that are built-in 2 pieces and could fire bullets of 300 kgs at a range of 1600 meters. They came to weigh almost 17 tons.

Falconets were also manufactured. They were small bronze cannons, whose main task was to cause damage to people. It was widely used, especially on boats. (image of a ship in Seville)

Bell metal

This alloy consists of 78% copper and 22% tin. This type of bronze was known since ancient times in India to make gongs. To obtain a more crystalline structure and produce variations in loudness, smelters have also used other metals such as antimony or bismuth in small quantities. Different alloys make different sounds.